We have realized overtime that Tononoka are reliable, affordable and efficient suppliers and unreservedly recommend them for their good quality products.

Square Hollow Sections (SHS) are made to the Kenya Bureau of Standards specification KS02-104:2001. They are used for structural purposes, in the furniture industry, fabrication, the component industry, etc.

The manufacturing process is similar to that of Black Round Pipes after which the pipes pass through sizing rolls and their profiles are converted into Square Hollow Sections.

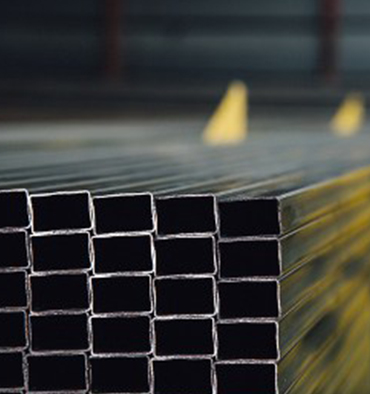

Rectangular Hollow Sections (RHS) are made to the Kenya Bureau of Standards specification KS02-104.They are manufactured on the tube mills using a high frequency induction welding technique.

The strip is continuously seam-welded while round in shape and then gradually brought to the desired section in the sizing mill. The welded seam’s strength is maximized by the cooling of each length of hollow section.

Black pipes are made to the Kenya Bureau of Standards specification KS06-259:1998 or the equivalent British International Standard BS:1387. They can be plain or bevel ended depending on the application. These pipes are meant for the conveyance of water, compressed air ad fluids. They are also used for water borehole casting pipes. They restrict the collapse of overburden soil. Slots are cut on the pipes for screening purposes depending on the application. Tononoka Steels Ltd uses the highest quality of Hot Rolled Coils (HRC) for this purpose. The HRC is slit suitably and fed into the most modern pipe rolling mills.

Gradually the mill shapes them from flat strips to the required circular pipe profile while the edges are prepared for high frequency welding. The bead is then cleaned for residual bead height with a carbide scraping tool online. A flying shear then cuts the pipe to the exact length required. The pipes are finally end-faced and hydro-tested on a special machine at a pressure of 50kg/cm2 for 15 seconds before being dispatched.

Galvanized pipes are manufactured to international standards as specified by the Kenya Bureau of Standards KS06-259:1998 or the equivalent British Standard BS- 1387. Galvanization is a process of applying a protective zinc coating to steel or iron, to prevent rusting. It entails plain ended black pipes being dipped in tanks containing sodium metasilicate (to degrease) and hydrochloric (to remove mill scale) solution after which they are rinsed in clean running water.

The rinsed pipes are then dipped in flux (zinc ammonium chloride) to facilitate the zinc coating adhesion before being immersed into a hot zinc bath. Zinc is deposited on the entire surface of the pipe and excess zinc is blown out via a hot pressurized steam. After this stage, if required, the pipes are threaded and socketed. Pipes are finally ready for dispatch.